The Critical Role of Data Annotation in Manufacturing

Empowering Manufacturing through Data Annotation

In modern manufacturing, data has risen to prominence as a key driver of operational excellence and informed decision-making. Among various data-related processes, accurate data labeling is integral to development of AI models.

In this article, we explore the significance of data labeling in manufacturing, shedding light on the concrete business value it delivers.

What is Data Labeling?

Data labeling involves systematically categorizing and tagging data points within a dataset.

For manufacturing, this encompasses a wide array of data sources, from production records and quality metrics to equipment specifications and maintenance logs. Accurate data labeling adds structure to raw data, enabling its transformation into actionable insights that guide process improvements and strategic choices.

Operational Efficiency

At the heart of effective manufacturing lies the drive for streamlined operations and optimal resource utilization.

By labeling data linked to distinct production stages, quality assessments, and equipment performance, manufacturers can identify operational bottlenecks and inefficiencies.

Picture a scenario where data analysis pinpoints specific production stages. A stage is causing delays, and your analysis shines light on facilitating timely interventions and resource allocation. This not only accelerates production but also curbs wastage, contributing to sustainable manufacturing practices.

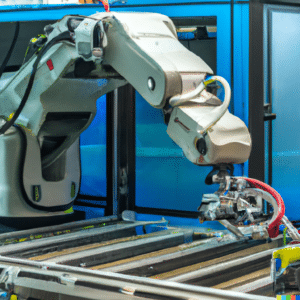

Predictive Maintenance

Maintenance is integral to manufacturing efficiency. Accurate data labeling proves invaluable here.

By labeling data related to equipment behavior, usage patterns, and maintenance history, manufacturers can develop predictive maintenance models.

These models forecast potential machinery failures, allowing for proactive maintenance that minimizes unplanned downtime, prevents production disruptions, and extends equipment lifespans.

Enhancing Quality Control

Product quality is non-negotiable in manufacturing.

Accurate data labeling plays a vital role in achieving and sustaining high quality of products.

By labeling data connected to quality inspections, defects, and production variables, manufacturers can implement data-driven quality control measures. This involves identifying patterns that correlate with defects, enabling real-time adjustments to production processes. The outcome:

-

lower defect rates

-

improved product consistency

-

heightened customer satisfaction.

Supply Chain Management

A resilient supply chain is pivotal in manufacturing success, and accurate data labeling contributes significantly.

Labeling data related to supplier performance, lead times, and inventory levels empowers manufacturers to optimize supply chain operations. This entails data-driven supplier evaluations, demand forecasts, and inventory replenishment strategies.

The result is a supply chain that is agile, cost-effective, and equipped to navigate market fluctuations.

Enhanced Decision-Making

In the ever-evolving landscape of manufacturing, informed decisions are how progress is made.

Labeling data associated with market trends, customer preferences, and emerging technologies equips manufacturers with insights for strategic planning.

This might entail adopting novel manufacturing processes, introducing innovative products, or exploring new markets based on robust data-driven insights.

Accurate data labeling transcends a routine task; it’s an investment that propels efficiency, quality, and strategic flexibility.

In an era where data-driven insights define manufacturing success, those who recognize the potential of accurate labeling are poised to navigate the industry’s future.